Product Description

BSPT Thread Design

The 13011 fittings feature British Standard Pipe Tapered (BSPT) male threads. BSPT threads are globally recognized and widely used in the industry. The tapered nature of these threads is a key advantage. As the male BSPT thread is screwed into a corresponding female BSPT thread, the taper allows for a self - sealing effect. The increasing contact pressure along the length of the thread as it is tightened creates a tight seal, effectively preventing fluid leakage. This design is especially suitable for applications where high - pressure fluid transfer is involved, such as in hydraulic machinery and industrial pipelines. The standardization of BSPT threads also ensures compatibility with a vast array of other BSPT - threaded components, facilitating easy installation and system integration.

60 - Degree Cone Seal

In addition to the BSPT threads, these fittings often incorporate a 60 - degree cone design at the connection point. When mated with a complementary female component having a 60 - degree cone seat, a metal - to - metal seal is formed. The 60 - degree angle is precisely engineered to provide an optimal fit. This cone - seal design further enhances the sealing performance of the fitting, especially in high - pressure scenarios. The combination of the BSPT thread and the 60 - degree cone seal ensures a robust and reliable connection, capable of withstanding the forces exerted by the fluid being transferred.

Straight - Through Configuration

The 13011 BSPT Male Fittings typically have a straight - through body design. This design allows for a smooth and unrestricted flow of fluids. In applications where maintaining a consistent flow rate and minimizing pressure drops are essential, such as in high - performance hydraulic systems, the straight - through configuration of these fittings proves highly beneficial. It reduces turbulence within the fluid stream, ensuring that the fluid can move freely from one part of the system to another without significant resistance. This not only improves the overall efficiency of the fluid - transfer system but also helps in preserving the integrity of the fluid and the components it passes through.

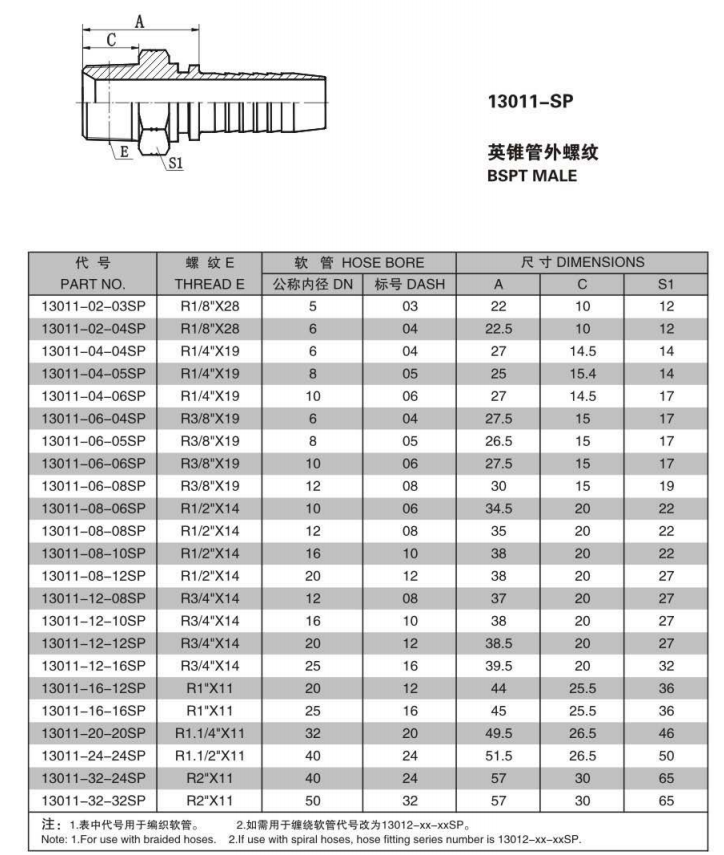

Specification

| Material: | Stainless steel、Carbon Steel、copper |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Carton case |

| Color: | silver |

Advantage

In terms of connection performance

Installation Convenience: Most hydraulic hose fittings are simply designed. For example, quick couplings do not require complex tools or professional skills. The connection and disconnection can be quickly completed by hand or through simple operations.

Firm Connection: Take the crimped hose fitting as an example. Through the crimping process, the fitting and the hose are closely combined. In addition, hydraulic pipe fittings with protective structures prevent loosening through the cooperation of threads and the limiting structure. They can maintain a reliable connection under working conditions such as high pressure and vibration.

Strong Adaptability: There are a variety of specifications, forms and connection methods, which can meet the connection requirements of hydraulic systems with different pipe diameters, pressures, media and installation requirements. They can be well adapted to various hydraulic components such as pumps, valves, and cylinders.

In terms of Sealing Performance

Prevention of Leakage: Advanced sealing technologies and high-quality sealing materials, such as O-rings and sealing rings, are adopted, which can effectively prevent the leakage of media such as hydraulic oil, ensuring the stability of the system pressure and the transmission efficiency of the media.

Maintaining Cleanliness: Good sealing performance can prevent external impurities such as dust and moisture from entering the hydraulic system, avoiding system contamination and component wear, and extending the service life of the system and components.

In terms of Working Performance

High Pressure Resistance: These fittings are made of materials such as high-strength metals or high-performance plastics. Through special processing and treatment, they can withstand relatively high working pressures.

Vibration and Flexure Resistance: The hoses of metal hose fittings are hydraulically formed thin-walled stainless steel tubes, which have excellent flexibility and vibration resistance. They can adapt to situations such as equipment vibration, displacement, and distortion, protecting the hoses and ensuring the stable operation of the system.

Corrosion Resistance: Fittings made of stainless steel possess strong chemical resistance and corrosion resistance. Plastic fittings can also operate in corrosive media such as acids and alkalis, making them suitable for harsh environments.

In terms of System Maintenance

Extended Lifespan: These fittings can protect hydraulic hoses from damage such as excessive bending, twisting, and stretching, preventing premature aging and rupture of hoses. For example, swivel hydraulic fittings can eliminate hose twisting, significantly extending the service life of hoses.

Easy Maintenance: In the event of a malfunction, only the damaged fitting needs to be replaced instead of the entire hose or system, reducing maintenance costs and difficulties. Moreover, some fittings are designed to facilitate inspection and repair.

Application

Hydraulic hose fittings are widely used, and the following are some of the main application areas:

Automotive Field

Braking System: When a vehicle brakes, the brake fluid flows from the master cylinder to the wheel cylinders, and it needs to be connected through high-pressure hoses and quick couplings. The quality of these fittings directly affects the braking effect and driving safety.

Steering System: In the power steering system, hydraulic hose fittings are responsible for connecting components such as the power steering pump and the steering gear, enabling the driver to easily operate the steering wheel.

Suspension System: The hydraulic suspension system relies on hydraulic hose fittings to connect components such as hydraulic cylinders, achieving the shock absorption of the vehicle and the adjustment of the vehicle body height.

Construction Machinery Field

Excavators: Hydraulic oil is conveyed to actuating components such as the bucket and the breaker through components like the main pump and the distribution valve. Hydraulic hose fittings need to withstand harsh environments such as high pressure, high temperature, and high friction to ensure the normal operation of the hydraulic system.

Cranes: These fittings are used to connect components of the crane, such as the hydraulic pump, hydraulic cylinders, and hydraulic motors, ensuring smooth and precise movements like lifting, luffing, and slewing.

Bulldozers: They enable the hydraulic system of the bulldozer to achieve reliable connections between various hydraulic components during high-load operations, guaranteeing the smooth implementation of functions such as earthmoving and soil loosening.

Industrial Automation Field

Machining Equipment: In the hydraulic systems of machining centers, numerically controlled machine tools and other equipment, hydraulic hose fittings connect the hydraulic station, hydraulic cylinders and hydraulic valves, etc., providing power for the feeding of cutting tools, the movement of the worktable and other operations.

Automated Production Lines: In automated production lines such as automobile assembly lines and food filling lines, they are used to connect various hydraulically driven robotic arms, fixtures, etc., to achieve operations such as material handling and assembly.

Robots: In hydraulically driven robots, hydraulic hose fittings connect the hydraulic source to the joint hydraulic cylinders of the robot, enabling the robot to perform various complex movements.

Other Fields

Agricultural Machinery: The hydraulic systems of agricultural machinery such as tractors, combine harvesters, and seeders rely on hydraulic hose fittings to connect various components and complete farmland operations.

Oil and Gas Industry: In the hydraulic systems of drilling, pumping, oil field operations and other processes, hydraulic hose fittings with high pressure resistance, high temperature resistance and corrosion resistance are used to prevent leakage and ensure the safe and stable operation of the system.

Transportation Industry: In railway, aviation and marine transportation, hydraulic hose fittings are required for the hydraulic systems that control key components such as brakes, lifting mechanisms, steering systems and suspensions. This ensures that the hydraulic systems of transportation vehicles can operate stably in high-load and high-vibration environments.