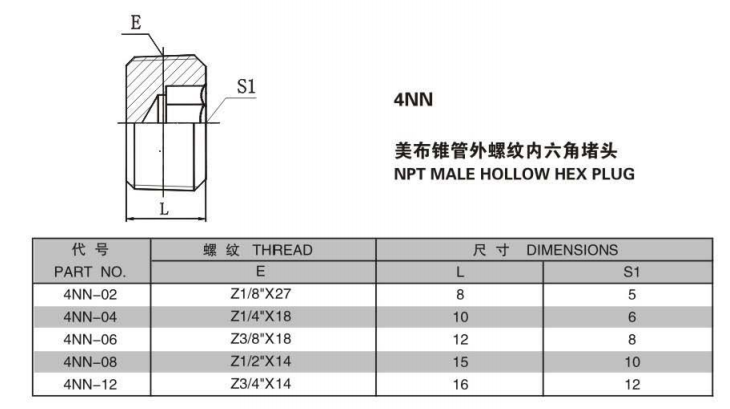

Product Description

NPT Male Threads

It comes with National Pipe Thread (NPT) male threads, which are tapered. This design allows for a secure and leak - tight connection when mated with corresponding female NPT fittings. The NPT standard is widely recognized and used across various industries, ensuring compatibility with a vast range of pipes, valves, and other plumbing or fluid - transfer components. The tapered threads create a seal as they are tightened, reducing the risk of fluid leakage under pressure.

Hollow Hex Structure

The hollow hexagon shape of the plug serves multiple purposes. The hollow center can be utilized in certain applications to allow for the passage of small tools, probes, or even for the insertion of fluids in specific scenarios where a non - solid closure is required. The hexagon shape, on the other hand, provides a large and convenient surface for gripping. This enables easy installation and removal using standard hex - key wrenches or sockets, making the process more efficient and less time - consuming. Whether in a large - scale industrial setting or a small - scale DIY project, the hollow hex design simplifies the handling of the plug.

Specification

| Material: | Stainless steel、Carbon Steel、copper |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Carton case |

| Color: | silver |

Advantage

In terms of sealing performance

Prevention of leakage: It can tightly seal the ends of hoses, preventing the leakage of internal media such as liquids and gases, thus avoiding resource waste and safety accidents. For example, in industrial oil pipelines and gas hoses, the plugs ensure that the media do not leak.

Maintenance of stable pressure: In systems with pressure requirements, it maintains the stability of the system pressure and ensures the normal operation of equipment. For instance, in hydraulic systems, it prevents the pressure from dropping due to leakage at the pipe ends.

In terms of maintenance and protection

Facilitating maintenance: During maintenance, install the plugs at both ends of the hose to isolate the maintenance section from the system. This makes it convenient for workers to operate without affecting the operation of other parts. For example, when conducting local pipeline repairs, it can avoid emptying the media of the entire system.

Protecting internal cleanliness: It effectively blocks external dust, debris, moisture, etc. from entering the hose, preventing internal blockages and corrosion, and extending the service life of the hose and related equipment. For example, the plugs for liquefied natural gas unloading hoses can prevent sand and dust from entering.

In terms of operation and use

Convenient installation: The installation method is simple, such as threaded connection, clamp connection, plug - in connection, etc. It does not require complex tools or professional skills, reducing construction difficulty and cost, and saving time and labor.

In terms of safety and environmental protection

Avoiding safety hazards: In pipeline systems carrying flammable, explosive, toxic and harmful media, it prevents media leakage that could trigger safety accidents such as fires, explosions and poisonings, safeguarding the safety of personnel and equipment. For example, the plugs for explosion - proof junction boxes can prevent explosive gases from entering.

Meeting environmental protection requirements: It prevents media leakage from polluting the environment and protects the ecological environment. For example, for hoses in chemical enterprises that transport chemical substances, the plugs can avoid the leakage of chemical substances from polluting the soil and water sources.

Application

Industrial Sectors

Chemical Industry: In chemical production, for hoses used to transport various chemical fluids, when maintaining, debugging or replacing equipment, plugs are used to seal the hose joints to prevent the leakage of chemical substances.

Oil and Gas Industry: During the processes of oil and gas exploration, transportation and storage, plugs are used to seal hose joints such as sampling ports and vent ports, ensuring the tightness and safety of the system and preventing oil and gas leakage.

Automotive Manufacturing Industry: In parts of the automotive fuel system, braking system and other areas involving hoses, plugs are used to temporarily block hoses during the production process to prevent impurities from entering or to prevent oil leakage during maintenance.

Aerospace Field: In the pipelines of aircraft or spacecraft hydraulic systems, fuel systems, etc., plugs are used to seal hose joints that are not in use for the time being, ensuring the tightness and reliability of the system in different working stages.