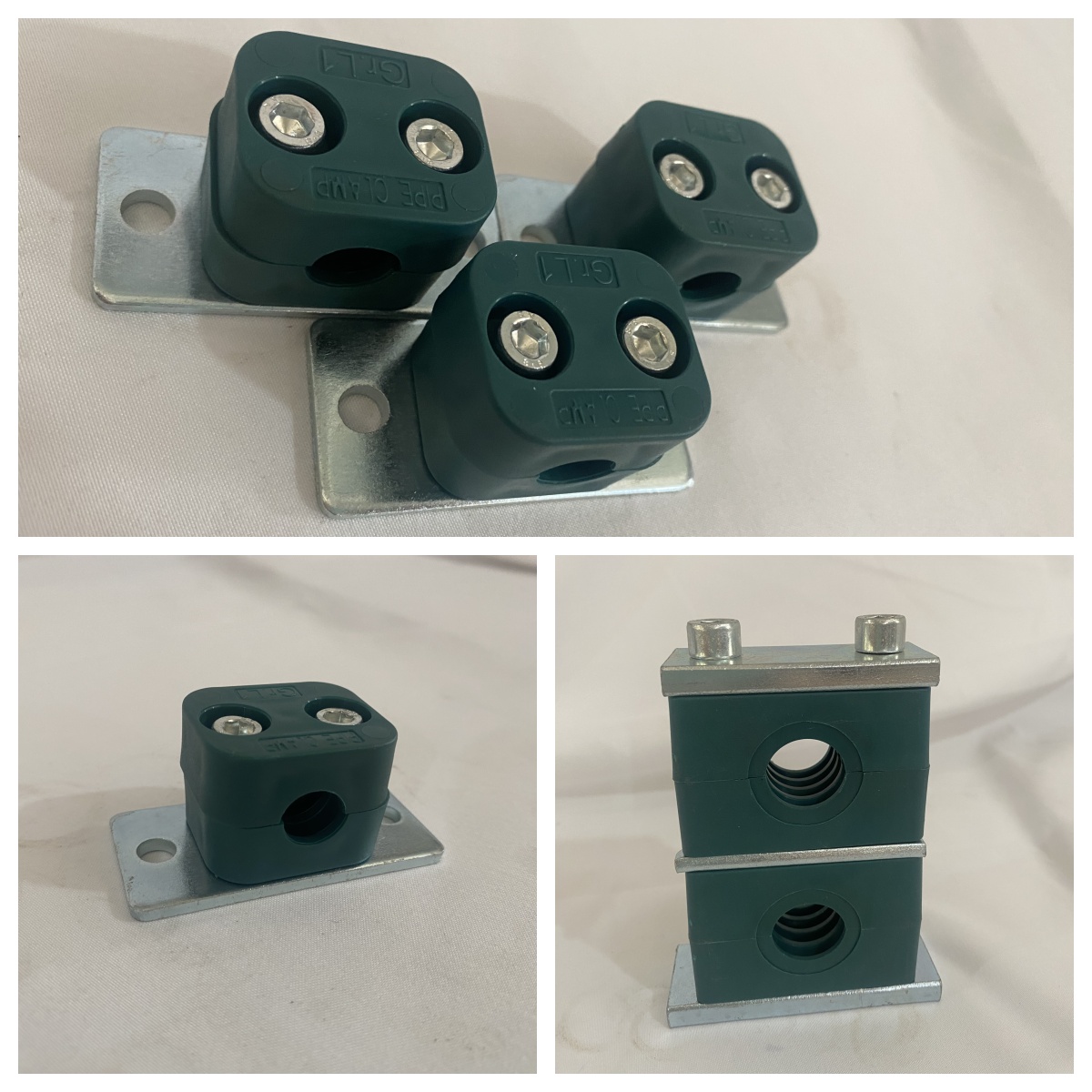

Product Description

Diverse Adaptability

From U - bolt clamps for heavy - duty industrial use to spring - loaded clamps for accommodating thermal expansion, each type offers specialized solutions tailored to specific operational demands, ensuring optimal pipe support in every scenario.

Superior Holding Power

U - bolt and weld - on clamps provide unrivaled stability, firmly securing pipes even in high - vibration, high - pressure environments, preventing leaks and system failures.

Exceptional Durability

Constructed from high - grade materials like stainless steel and robust alloys, these clamps resist corrosion, abrasion, and harsh conditions, ensuring long - term reliability and reduced maintenance.

Enhanced System Performance

Enhanced System PerformanceBy minimizing pipe movement and vibration, all types of hydraulic pipe clamps contribute to smoother fluid flow, improved system efficiency, and extended equipment lifespan.

Specification

| Material: | Stainless steel、Carbon Steel、copper |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Carton case |

| Color: | silver |

Advantage

Excellent Fixation Effect

It can securely fasten hydraulic pipelines in designated positions, preventing the pipelines from displacement, swaying, or mutual collision caused by factors such as vibration and pressure fluctuations. This ensures the stability and reliability of the hydraulic system.

Pipeline Protection

Pipe clamps prevent direct contact between pipelines and other components, reducing friction and wear. They also shield pipelines from external mechanical damage, significantly extending the service life of the pipelines.

Vibration Damping and Noise Reduction

Hydraulic systems generate vibrations and noise during operation. Hydraulic pipe clamps, typically made from elastic materials, can absorb part of the vibration energy, effectively damping vibrations and reducing noise. This helps create a more comfortable and quieter working environment.

Easy Installation and Maintenance

Hydraulic pipe clamps feature a simple structure, enabling effortless installation and disassembly. This convenience facilitates the setup, debugging, repair, and replacement of hydraulic pipelines, significantly enhancing work efficiency and reducing maintenance costs.

Adaptability to Diverse Environments

Hydraulic pipe clamps can be selected based on different working conditions and medium requirements. For instance, in high - temperature, humid, or corrosive environments, materials with high heat resistance and corrosion resistance can be chosen. This ensures that the pipe clamps maintain optimal performance and a long service life, adapting seamlessly to various environmental challenges.

Improved Space Utilization

The rational arrangement of pipe clamps enables hydraulic pipelines to be neatly and orderly arranged, effectively maximizing space usage. This results in a more compact and aesthetically pleasing layout of the hydraulic system. Additionally, it facilitates easier inspection and maintenance for operators, enhancing overall operational convenience.

Guaranteed System Performance

Through excellent fixation and support, hydraulic pipe clamps help maintain the correct alignment and slope of hydraulic pipelines. This ensures the smooth flow of hydraulic oil, preventing issues such as cavitation and eddies, thereby stabilizing the performance of the hydraulic system.

Application

Hydraulic hose fittings are widely used. The following are some of the main application areas:

Industrial Machinery

In the hydraulic systems of industrial equipment such as machine tools, injection molding machines, and presses, hydraulic pipe clamps are used to secure hydraulic pipelines, ensuring the stable operation of the systems. For example, in the hydraulic transmission system of a machine tool, pipe clamps are employed to fix the oil pipes, guaranteeing the stable delivery of hydraulic oil and enabling precise motion control of various machine tool components.

Construction Machinery

Construction machinery such as excavators, loaders, and cranes have hydraulic systems that endure significant pressure and vibration. Hydraulic pipe clamps can firmly secure the pipelines, preventing loosening or wear caused by vibration, thus enhancing the reliability and durability of the systems. Take excavators as an example; pipe clamps fix the hydraulic oil pipes on components such as the boom, arm, and slewing platform, ensuring that the hydraulic system can operate normally in complex working environments.

Aerospace

In the hydraulic systems of aircraft, there are extremely high requirements for the fixation and reliability of pipelines. Hydraulic pipe clamps must possess high strength, light weight, and excellent vibration resistance to ensure the safe and stable operation of the hydraulic system during flight. For instance, the hydraulic system of an aircraft's landing gear uses pipe clamps made of special materials, which can not only withstand high pressure but also reduce the overall weight of the aircraft.

Shipbuilding

The hydraulic systems of ships are used to control equipment such as ship rudders, anchor windlasses, and cranes. The application of hydraulic pipe clamps on ships requires the property of resistance to seawater corrosion to ensure long-term and stable operation in harsh marine environments. For example, the hydraulic pipelines of the rudder are fixed to the ship's bulkhead by corrosion-resistant pipe clamps, ensuring accurate and reliable steering control of the ship.

Automobile Manufacturing

Hydraulic pipe clamps play an important role in the hydraulic systems of automobiles, such as the power steering system and the braking system. They fix the hydraulic pipelines in the vehicle's chassis and engine compartment, ensuring that the pipelines will not be damaged due to vibrations and jolts during the vehicle's operation, thus improving the safety and reliability of the automobile. For example, the oil pipes in the power steering system of a car are fixed to the vehicle frame by pipe clamps, enabling the driver to easily control the steering wheel.