Product Description

Precise 90° Bend

The most prominent feature of 1C9 and 1D9 elbow fittings is their precisely crafted 90° bend. This angular design allows for a smooth and controlled change in the flow path of liquids or gases. The bend radius is optimized to minimize turbulence and pressure drop during the flow transition. By reducing turbulence, these fittings help maintain the integrity of the fluid flow, which is essential for the efficient operation of the overall system. Whether it's a high - pressure hydraulic system or a low - flow plumbing application, the well - designed 90° bend ensures that the fluid can be redirected without significant energy loss.

Dual - End Connections

These elbow fittings are equipped with male threads and compression nuts on both ends, along with sleeves. The male threads are designed to securely mate with corresponding female threads on pipes or other fittings. The compression nuts and sleeves work in tandem to create a leak - tight seal. When the compression nut is tightened, the sleeve is forced against the pipe, creating a tight grip that prevents any fluid leakage. This dual - end connection design makes it easy to integrate the 1C9 and 1D9 elbow fittings into existing piping systems. They can be connected to pipes of various materials, provided that the thread types and sizes are compatible.

High - Pressure Resistance

1C9 and 1D9 elbow fittings are engineered to handle high - pressure fluid systems. Depending on the material and construction, they can withstand pressures ranging from moderate to extremely high levels. For example, carbon steel fittings with proper wall thickness and surface treatment can handle high - pressure hydraulic applications in industrial machinery, where pressures can reach several hundred bar. Stainless steel fittings, due to their superior material properties, can also endure high - pressure environments, making them suitable for use in oil and gas pipelines, where the fluids are often transported under high pressure. This high - pressure resistance ensures the safe and reliable operation of the fluid transfer system, preventing any potential leaks or failures that could lead to equipment damage or safety hazards.

Leak - Proof Sealing

The compression nut and sleeve design of these elbow fittings provides a reliable leak - proof seal. When properly installed, the sleeve deforms slightly under the pressure of the tightened compression nut, creating a tight seal around the pipe. This multi - layer sealing mechanism effectively prevents any fluid from escaping, even in systems with high - pressure differentials or in applications where the fluid is highly volatile. In applications such as chemical plants, where the leakage of hazardous fluids could have serious consequences, the leak - proof performance of 1C9 and 1D9 elbow fittings is of utmost importance. The high - quality materials used in the construction of the fittings, along with the precision - engineered sealing mechanism, ensure that the integrity of the fluid system is maintained over an extended period.

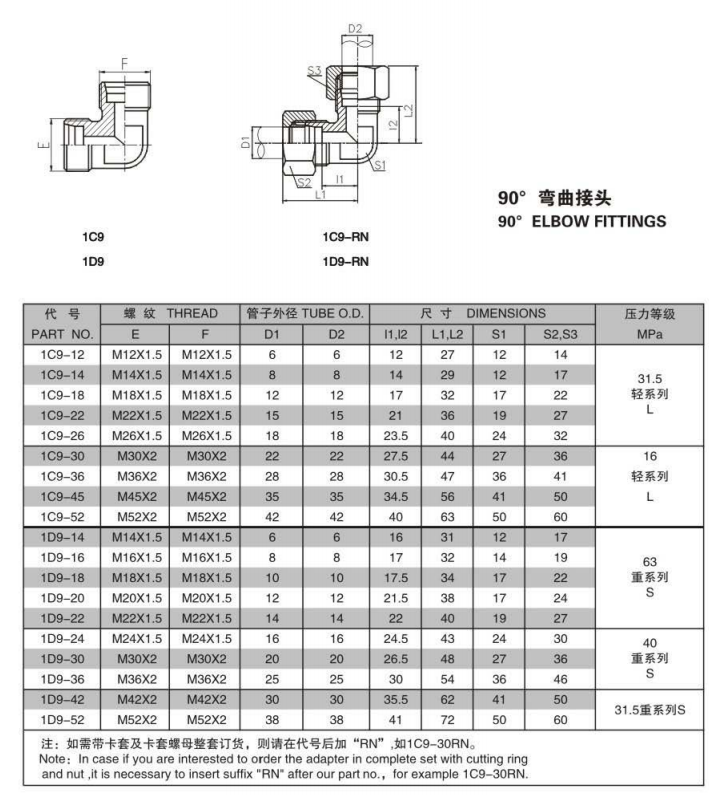

Specification

| Material: | Stainless steel、Carbon Steel、copper |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Carton case |

| Color: | silver |

Advantage

Convenient Installation

Simple Operation: During installation, you just need to insert the pipe into the ferrule fitting and tighten the nut with a wrench. There is no need for complex operations such as welding or flaring, which can save a great deal of installation time and labor costs.

No Special Tools Required: Generally, only commonly used tools like wrenches are needed to complete the installation. Unlike some other fittings that require specialized welding equipment or flaring tools, this reduces the installation threshold and equipment requirements.

Reliable Connection

Good Sealing Performance: When the nut is tightened, the ferrule will deform and firmly grip the pipe, forming multiple sealing barriers. This can effectively prevent the leakage of hydraulic oil and ensure the sealing and stability of the hydraulic system.

Strong Vibration Resistance: During the operation of the hydraulic system, even in the presence of vibrations and impacts, the clamping force between the ferrule and the pipe can ensure that the connection will not loosen, maintaining the normal operation of the system.

High Compatibility

Suitable for Multiple Pipe Materials: It can be connected to pipes made of various materials such as steel pipes, copper pipes, and stainless - steel pipes, meeting the requirements of different hydraulic systems for pipe materials with a wide range of applications.

Multiple Pressure Ratings Available: There are products of different specifications and pressure ratings for selection. They can adapt to various hydraulic systems ranging from low pressure to high pressure, meeting the usage requirements under different working conditions.

Convenient Maintenance

Easy Disassembly: When it is necessary to repair or replace components, simply loosen the nut, and the ferrule fitting can be removed from the pipe without causing damage to either the pipe or the fitting, which facilitates subsequent repair and replacement work.

Reusable: After the ferrule fitting is disassembled, if components such as the ferrule and nut are not damaged, they can be used again, reducing the maintenance cost.

Tidy Appearance

Aesthetically Pleasing After Installation: Compared with connection methods such as welding, the ferrule fitting presents a neater and more aesthetically pleasing appearance after installation. There will be no traces like welding scars left behind, making the overall layout of the hydraulic system more regular.

Application

The hydraulic ferrule fitting is a commonly used connecting component in hydraulic systems and has a wide range of applications, mainly reflected in the following fields:

Industrial Machinery

Machine Tool Equipment: It is used to connect the hydraulic pipelines of machine tools, such as the connections between hydraulic pumps, hydraulic cylinders and control valves, ensuring the smooth transmission of hydraulic oil and achieving precise control of actions such as the feed of the machine tool worktable and the clamping of the cutting tool.

Injection Molding Machines: In the hydraulic system of injection molding machines, it connects various hydraulic components. For example, it conveys the high-pressure oil output by the oil pump to the mold clamping cylinders, injection cylinders, etc., ensuring the stable execution of process actions such as mold clamping, injection, and pressure holding of the injection molding machine.

Construction Machinery

Excavators: Applied in the hydraulic system of excavators, it connects the hydraulic oil pipes, supplies pressure oil to the hydraulic cylinders of working devices such as the digging arm and the bucket, enabling operations like digging and loading/unloading. It is also used to connect the hydraulic motors to drive the traveling mechanism and the slewing mechanism.

Cranes: In the hydraulic systems for hoisting, luffing, slewing, etc. of cranes, the hydraulic ferrule fittings connect various hydraulic components into a complete system, allowing the crane to safely and efficiently complete the tasks of lifting and handling heavy objects.

Automobile Manufacturing and Maintenance

Automobile Production: In the hydraulic equipment on the automobile production line, such as the stamping machines for automobile parts and hydraulic fixtures, the hydraulic ferrule fittings are used to connect the hydraulic pipelines, ensuring the normal operation of the equipment and improving production efficiency and product quality.

Automobile Maintenance: During the process of automobile maintenance, it is used to connect the maintenance equipment with the hydraulic system of the automobile. For example, when repairing the automobile braking system, it connects the brake fluid filling equipment with the automobile braking pipeline, ensuring the smooth progress of the maintenance and debugging work of the braking system.

Metallurgical Industry

Steel Rolling Equipment: In the hydraulic screw-down system and hydraulic roll bending system of steel rolling mills, hydraulic ferrule fittings connect the hydraulic pipelines, providing reliable hydraulic connections for the adjustment of the position of the rolls, the control of the rolling force, etc., ensuring the rolling accuracy and quality of steel products.

Smelting Equipment: It is used to connect the hydraulic pipelines of the hydraulic tilting devices of smelting furnaces, hydraulic clay guns and other equipment, ensuring that these devices can operate stably in a high-temperature and harsh working environment and complete operations such as furnace tilting and tapping hole blocking.

Shipbuilding Industry

Ship Power System: In the main engine starting system and steering gear hydraulic system of ships, hydraulic ferrule fittings are used to connect the hydraulic pipelines, providing reliable hydraulic connections for the power transmission and direction control of ships, ensuring the safe navigation of ships.

Ship Loading and Unloading Equipment: In the hydraulic systems of ship loading and unloading equipment such as ship cranes and winches, hydraulic ferrule fittings connect various hydraulic components, enabling various actions of the loading and unloading equipment and improving the loading and unloading efficiency of ships.