Product Description

High - Quality Base Material

These ferrules are crafted from premium - grade materials, typically carbon steel or stainless steel. Carbon steel provides excellent mechanical strength, making it suitable for general - purpose applications where robustness is required. It can withstand significant mechanical stress during the installation and operation of the hose assembly. Stainless steel, on the other hand, is chosen for its superior corrosion - resistant properties. In environments where the ferrule may be exposed to moisture, chemicals, or harsh weather conditions, stainless steel ensures long - term durability without succumbing to rust or degradation.

Surface Treatment

To further enhance their performance and lifespan, the 00018 ferrules often undergo surface treatment processes. Common treatments include zinc plating, which creates a protective barrier against corrosion. This not only extends the ferrule's service life but also gives it an aesthetically pleasing finish. In some cases, more specialized coatings may be applied depending on the specific requirements of the application, such as coatings for enhanced lubricity or resistance to specific chemicals.

Precision - Engineered Fit

The inner diameter of the 00018 ferrules is precisely machined to match the outer diameter of SAE 100R7 hoses with extreme accuracy. This precision fit is crucial for achieving a tight and secure connection. A perfect fit minimizes the risk of leaks, as there are no gaps or spaces through which fluids could escape. The outer surface of the ferrule is also carefully designed to ensure compatibility with fittings and other components in the system, preventing any damage or interference during installation.

Pressure - Resistant Design

Engineered to handle the pressures associated with SAE 100R7 hoses, the 00018 ferrules are designed to withstand medium - pressure applications. They can endure the internal pressures generated within the hose during normal operation without deforming or failing. The robust construction and high - quality materials enable the ferrules to maintain their structural integrity, ensuring reliable performance over an extended period.

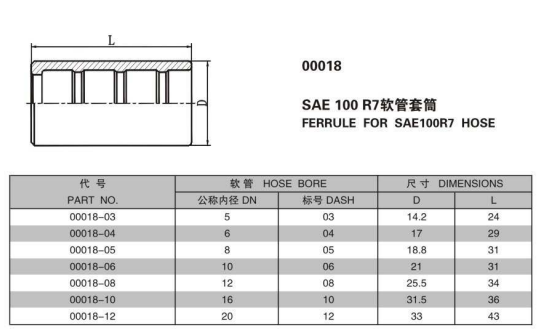

Specification

| Material: | Nitrile rubber、Stainless steel |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Carton case |

| Color: | black |

Advantage

It has excellent sealing performance

Preventing leakage: The hydraulic hose ferrule fits tightly with the hose and the connector, which can form an effective seal. It ensures the circumferential uniform distribution of the crimping pressure, achieving concentric sealing and preventing the leakage of hydraulic oil.

Adaptable to various working conditions: Even under complex working conditions such as vibration and pressure fluctuations, the ferrule can maintain its sealing performance, ensuring the stable operation of the hydraulic system.

It has a firm and reliable connection

Strong anti-pullout ability: The ferrule is connected to the hose through crimping and other methods, which can provide a powerful connection force. For example, in the ferrule of the high-pressure hose patent of Weifang Jiateng Hydraulics, the design of the convex teeth and the accommodating grooves on its inner side can ensure that the resin tube remains securely fastened after crimping, preventing the hose from coming off under high pressure.

High pressure resistance: It is manufactured from high-strength materials and can withstand relatively high hydraulic pressures.

Protect the hose

Enhanced wear resistance: The ferrule can protect the hose from external wear, scratches and other damages, thereby extending the service life of the hose. Especially when the hose is in contact with other components or operating in harsh environments, it can prevent the outer surface of the hose from being damaged.

Enhanced wear resistance: The ferrule can protect the hose from external wear, scratches and other damages, thereby extending the service life of the hose. Especially when the hose is in contact with other components or operating in harsh environments, it can prevent the outer surface of the hose from being damaged.Buffer pressure shock: It can, to a certain extent, buffer the pressure shock in the hydraulic system, reduce the instantaneous pressure changes on the hose, and lower the risk of the hose bursting or being damaged due to pressure shock.

Application

Mechanical manufacturing

In the hydraulic system of the robotic arm in the automated production line, the hydraulic hose ferrules connect various components to ensure the transmission of power, and they can adapt to the multi-angle and multi-directional movements of the robotic arm.

Petrochemical industry

In the processes of oil and natural gas extraction and refining, it is used in the hydraulic systems that connect drilling equipment, pumping equipment and other devices. It can withstand high pressure and resist chemical corrosion, ensuring the safe and stable operation of the systems.

Construction machinery

For construction equipment such as cranes and excavators, the hydraulic systems feature high pressure and strong vibrations. The hydraulic hose ferrules provide a firm connection and reliable sealing, which can improve the stability of the systems and extend their service life.

Agricultural machinery

The hydraulic systems of agricultural machinery such as tractors and combine harvesters connect various components through hydraulic hose ferrules, enabling them to operate normally in harsh outdoor environments and complex working conditions.

Ship transportation

It is applied to the hydraulic systems of ship cranes, deck mechanical equipment, etc., and can maintain good performance in corrosive environments such as the humidity and salt spray in the ocean.

Medical equipment

In the hydraulic systems of some medical equipment such as hydraulic operating tables and rehabilitation devices, the hydraulic hose ferrules ensure the precision and stability of hydraulic transmission, providing reliable support for medical operations.