Product Description

Corrosion - Resistant Base Material

These ferrules are constructed from top - grade materials, with a primary focus on corrosion resistance. Stainless steel alloys, often containing high percentages of chromium and nickel, are commonly used. Stainless steel offers excellent resistance to a wide range of chemicals, making it highly suitable for use in conjunction with TEFLON hoses, which are frequently employed in applications involving corrosive fluids. In some cases, specialized alloys may be utilized to further enhance chemical resistance, depending on the specific requirements of the application.

Compatibility with TEFLON

The material of the 00TF0 ferrules is carefully selected to be compatible with TEFLON. This compatibility ensures that there is no chemical reaction or degradation between the ferrule and the hose, maintaining the integrity of both components over time. It also helps in achieving a tight and stable connection, as the materials bond well without causing any damage or interference to the TEFLON hose.

Precision - Engineered Fit

The inner diameter of the 00TF0 ferrules is precisely machined to match the outer diameter of TEFLON hoses with extreme accuracy. This precision fit is crucial for creating a leak - proof connection. A perfect fit leaves no gaps or spaces through which fluids could escape, ensuring the safe and efficient transfer of substances. The outer surface of the ferrule is also designed to be smooth and free of any sharp edges or burrs that could potentially damage the TEFLON hose during installation or operation.

Chemical - Resistant Sealing Mechanisms

The 00TF0 ferrules are equipped with advanced chemical - resistant sealing mechanisms. These may include specialized gaskets or O - rings made from materials such as fluorocarbon elastomers, which offer excellent resistance to a broad spectrum of chemicals. The sealing mechanisms are designed to work in harmony with the TEFLON hose, providing a reliable barrier against leaks even in the presence of highly corrosive or aggressive fluids.

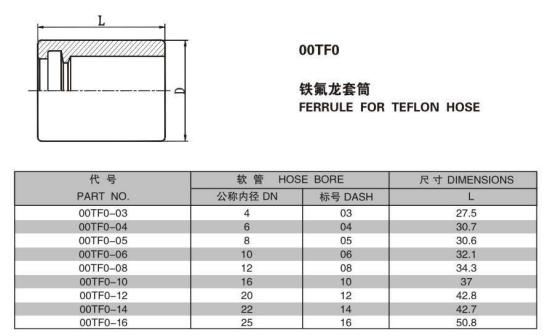

Specification

| Material: | Nitrile rubber、Stainless steel |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Carton case |

| Color: | black |

Advantage

Excellent chemical stability

High corrosion resistance: The Teflon sleeve can resist the erosion of various chemical substances, including strong acids, strong alkalis, strong oxidants, etc. When used in corrosive environments such as chemical industry and electroplating, it can protect internal components from damage by chemical substances.

Good solvent resistance: It is almost insoluble in any organic solvents. Even if it comes into contact with organic solvents for a long time, its performance will not be affected, and it can maintain excellent physical and chemical properties.

Good performance in resisting high and low temperatures

High temperature resistance: It can be used for a long time at a temperature of up to 260°C. In a short period, it can even withstand higher temperatures. When applied to the relevant components of industrial equipment in high-temperature environments, such as high-temperature ovens and furnaces, it can maintain stable performance and is not prone to deformation or damage.

Low temperature resistance: It can still maintain good flexibility and mechanical properties at extremely low temperatures. It can work normally in a low-temperature environment of -200°C, making it suitable for fields such as low-temperature freezing and cryogenic treatment.

Outstanding electrical insulation performance

High insulation: It has extremely high dielectric strength and volume resistivity, which can effectively prevent the passage of electric current. It can be used as an insulating protective sheath for wires and cables, and also in electronic and electrical equipment to isolate live components, preventing electric leakage and short circuits.

Low dielectric constant: During the signal transmission process, the low dielectric constant of the Teflon sleeve can reduce signal attenuation and distortion. It is widely used in fields involving high-frequency and high-speed signal transmission, such as 5G communication and the electronic systems of aerospace.

Low friction coefficient

Good self-lubrication: The surface of the Teflon sleeve is extremely smooth with an extremely low friction coefficient. When in contact with other objects, it can effectively reduce friction. It can be applied to mechanical components that require a reduction in friction loss, such as bearings and sliders, which can reduce energy consumption and improve the operation efficiency and service life of the equipment.

Strong anti-adhesion: It hardly adheres to any substances. In fields such as food processing and packaging machinery, it can prevent materials from sticking to the surface of the equipment, making it easy to clean and maintain, and improving production efficiency.

Good mechanical properties

High strength: Although the Teflon material is relatively lightweight, it has a high tensile strength and tear resistance. It can withstand a certain amount of external force and is not prone to cracking or damage.

Excellent flexibility: It has good flexibility and elasticity, and can be bent without breaking. It can adapt to components of different shapes and sizes. When used in some parts that need to be bent or moved frequently, such as the protective sleeves of hydraulic hoses, it can effectively protect the internal structure.

Application

In the Chemical Industry Field

Transportation of Corrosive Media: It is used to transport various highly corrosive chemical fluids such as sulfuric acid, nitric acid, and caustic soda. Thanks to its outstanding chemical stability, it can ensure that the hose is not corroded during the transportation process, thus guaranteeing the safe transfer of the media.

Connection of Chemical Reaction Devices: In the connections between equipment such as chemical reaction kettles and reactors, it can adapt to environments with high temperature, high pressure, and strong chemical corrosion, ensuring the smooth material transfer and reaction between the devices.

In the Field of Electronics and Electrical Engineering

Insulation Protection of Wires and Cables: Serving as an insulating sheath for wires and cables, it can provide high insulation performance, preventing electric leakage and short circuits. At the same time, it can maintain stable performance in high-temperature environments, ensuring the safe operation of electronic devices.

Internal Connection of Electronic Devices: Inside electronic devices such as computers and communication equipment, it is used to connect various electronic components and circuits. Its low dielectric constant can reduce the loss and distortion during signal transmission, ensuring the quality of signal transmission.

In the Food and Beverage Field

Pipelines of Food Processing Equipment: In food processing production lines, it is used to transport food materials such as fruit juices, sauces, and edible oils. Its non-toxic and non-sticky properties can prevent material residues and cross-contamination, and it is easy to clean, meeting food hygiene standards.

Connection of Beverage Filling Equipment: In beverage filling production lines, it connects each filling station and conveying pipeline. It can withstand certain pressure and temperature changes, ensuring the smooth and hygienic process of beverage filling.