Product Description

High - Quality Materials

The 00110 ferrules are made from high - grade materials, such as alloy steel or stainless steel. These materials are chosen for their excellent mechanical properties, including high strength, corrosion resistance, and durability. Alloy steel provides a good balance between strength and cost - effectiveness, making it suitable for most general - purpose hydraulic applications. Stainless steel, on the other hand, offers superior corrosion resistance, making it an ideal choice for applications where the ferrules may be exposed to harsh environments, such as in marine or chemical processing industries.

Secure Connection

One of the primary functions of the 00110 ferrules is to provide a secure connection between the SAE 100 R1AT/EN 853 1SN hoses and other hydraulic components, such as fittings or valves. When properly installed, the ferrules create a tight seal around the hose, preventing any leakage of hydraulic fluid. This is essential for maintaining the efficiency and reliability of the hydraulic system, as fluid leakage can lead to reduced pressure, loss of power, and potential damage to other components.

Simple Installation Process

Installing the 00110 ferrules onto SAE 100 R1AT/EN 853 1SN hoses is a straightforward process. With the right tools and following the recommended installation procedures, even users with limited technical expertise can quickly and easily attach the ferrules to the hoses. This ease of installation not only saves time but also reduces the likelihood of installation errors, which can compromise the performance of the hydraulic system.

Compatibility with Installation Tools

The 00110 ferrules are designed to be compatible with common installation tools used in the hydraulic industry. Whether you are using a manual crimping tool or an automated crimping machine, the ferrules can be effectively installed to ensure a proper and secure connection. This compatibility with various installation tools makes it convenient for users to choose the most suitable method for their specific application and available resources.

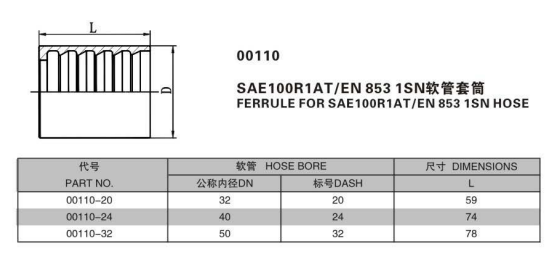

Specification

| Material: | Nitrile rubber、Stainless steel |

| Size: | All size |

| Weight: | *g |

| MOQ: | 100pcs |

| Packing: | Opp |

| Color: | black |

Advantage

It has excellent sealing performance

Preventing leakage: The hydraulic hose ferrule fits tightly with the hose and the connector, which can form an effective seal. It ensures the circumferential uniform distribution of the crimping pressure, achieving concentric sealing and preventing the leakage of hydraulic oil.

Adaptable to various working conditions: Even under complex working conditions such as vibration and pressure fluctuations, the ferrule can maintain its sealing performance, ensuring the stable operation of the hydraulic system.

It has a firm and reliable connection

Strong anti-pullout ability: The ferrule is connected to the hose through crimping and other methods, which can provide a powerful connection force. For example, in the ferrule of the high-pressure hose patent of Weifang Jiateng Hydraulics, the design of the convex teeth and the accommodating grooves on its inner side can ensure that the resin tube remains securely fastened after crimping, preventing the hose from coming off under high pressure.

High pressure resistance: It is manufactured from high-strength materials and can withstand relatively high hydraulic pressures.

Protect the hose

Enhanced wear resistance: The ferrule can protect the hose from external wear, scratches and other damages, thereby extending the service life of the hose. Especially when the hose is in contact with other components or operating in harsh environments, it can prevent the outer surface of the hose from being damaged.

Enhanced wear resistance: The ferrule can protect the hose from external wear, scratches and other damages, thereby extending the service life of the hose. Especially when the hose is in contact with other components or operating in harsh environments, it can prevent the outer surface of the hose from being damaged.Buffer pressure shock: It can, to a certain extent, buffer the pressure shock in the hydraulic system, reduce the instantaneous pressure changes on the hose, and lower the risk of the hose bursting or being damaged due to pressure shock.

Application

Mechanical manufacturing

In the hydraulic system of the robotic arm in the automated production line, the hydraulic hose ferrules connect various components to ensure the transmission of power, and they can adapt to the multi-angle and multi-directional movements of the robotic arm.

Petrochemical industry

In the processes of oil and natural gas extraction and refining, it is used in the hydraulic systems that connect drilling equipment, pumping equipment and other devices. It can withstand high pressure and resist chemical corrosion, ensuring the safe and stable operation of the systems.

Construction machinery

For construction equipment such as cranes and excavators, the hydraulic systems feature high pressure and strong vibrations. The hydraulic hose ferrules provide a firm connection and reliable sealing, which can improve the stability of the systems and extend their service life.

Agricultural machinery

The hydraulic systems of agricultural machinery such as tractors and combine harvesters connect various components through hydraulic hose ferrules, enabling them to operate normally in harsh outdoor environments and complex working conditions.

Ship transportation

It is applied to the hydraulic systems of ship cranes, deck mechanical equipment, etc., and can maintain good performance in corrosive environments such as the humidity and salt spray in the ocean.

Medical equipment

In the hydraulic systems of some medical equipment such as hydraulic operating tables and rehabilitation devices, the hydraulic hose ferrules ensure the precision and stability of hydraulic transmission, providing reliable support for medical operations.